Description

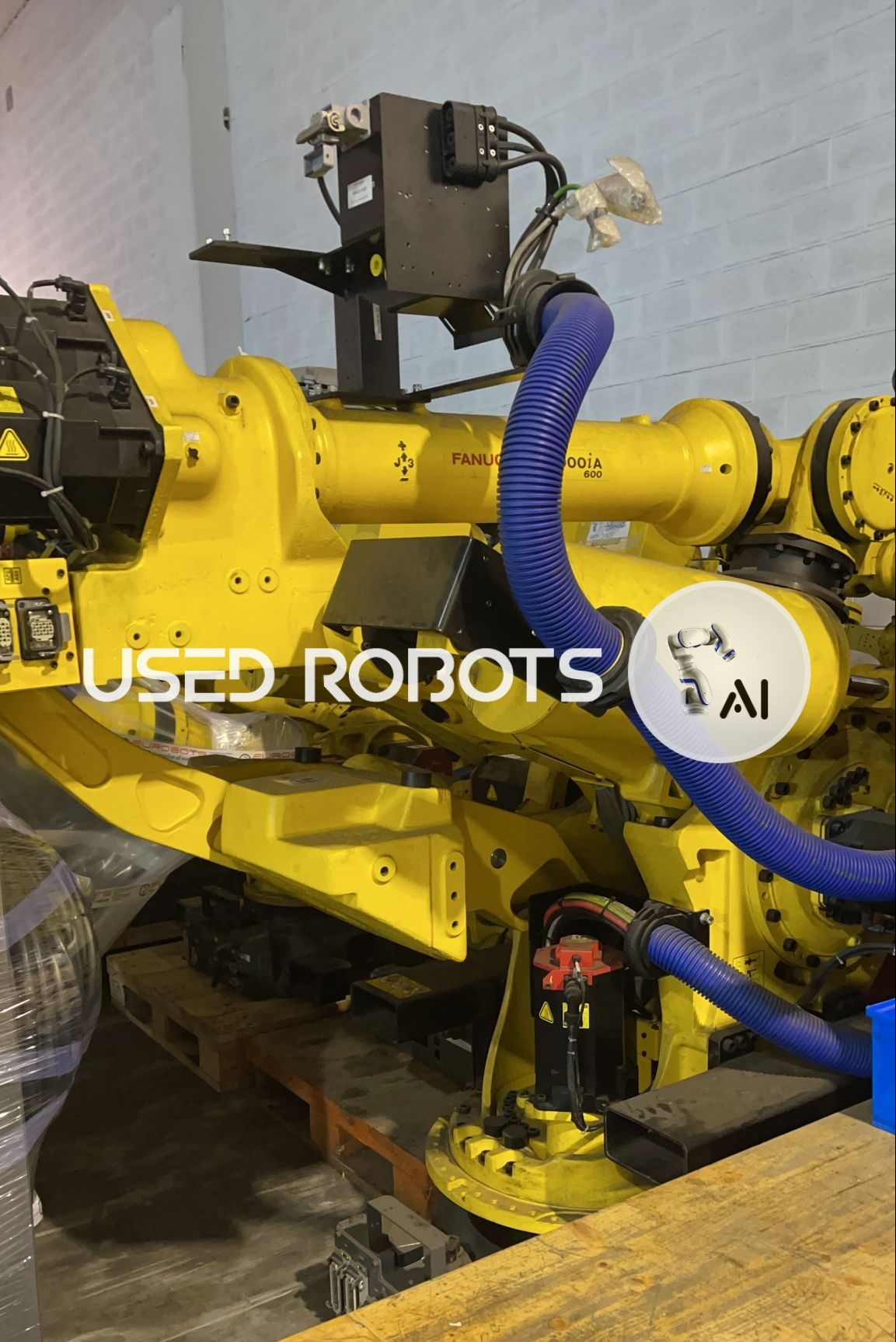

The robot FANUC M-900IA/600 stands out in the market due to its impressive payload capacity and reach, making it suitable for heavy-duty industrial applications. The R-30iA controller equipped with this robot offers several advanced features that contribute to its efficiency and usability.

The quick startup time of less than a minute, even quicker with basic software, ensures minimal downtime, which is crucial in industrial settings. Moreover, the ability to restart robot programs swiftly after a power failure, using the resume hotstart function, helps maintain continuous production without having to redo entire movements.

The resume tolerance check feature is particularly noteworthy, as it memorizes the robot’s position before an interruption and checks for any deviations when the program resumes. This prevents unexpected movements and potential collisions, enhancing safety and reliability in operations.

The controller’s vibration control capabilities, through enhanced hardware and software, contribute to better control over the robot’s movements, resulting in reduced acceleration and deceleration times. This reduction ultimately leads to improved cycle times, enhancing overall efficiency.

The wide range of connectivity options offered by the R-30iA controller, such as USB, PCMCIA interfaces, serial connections, and support for various peripherals like printers, sensors, and data transfer options, allows for versatile integration and ease of data backup and program transfer. The inclusion of the KAREL option for user-specific data transfer adds to its flexibility.

The FANUC iPendant, with its intelligent design and optional touch screen, provides an intuitive interface for easier interaction with the robot. Features like access to websites via Ethernet, status monitoring of peripheral equipment and other robots through HTML web server pages, a colored multi-window display, and customizable screens contribute to enhanced productivity and streamlined operation.

Reviews

There are no reviews yet.