Description

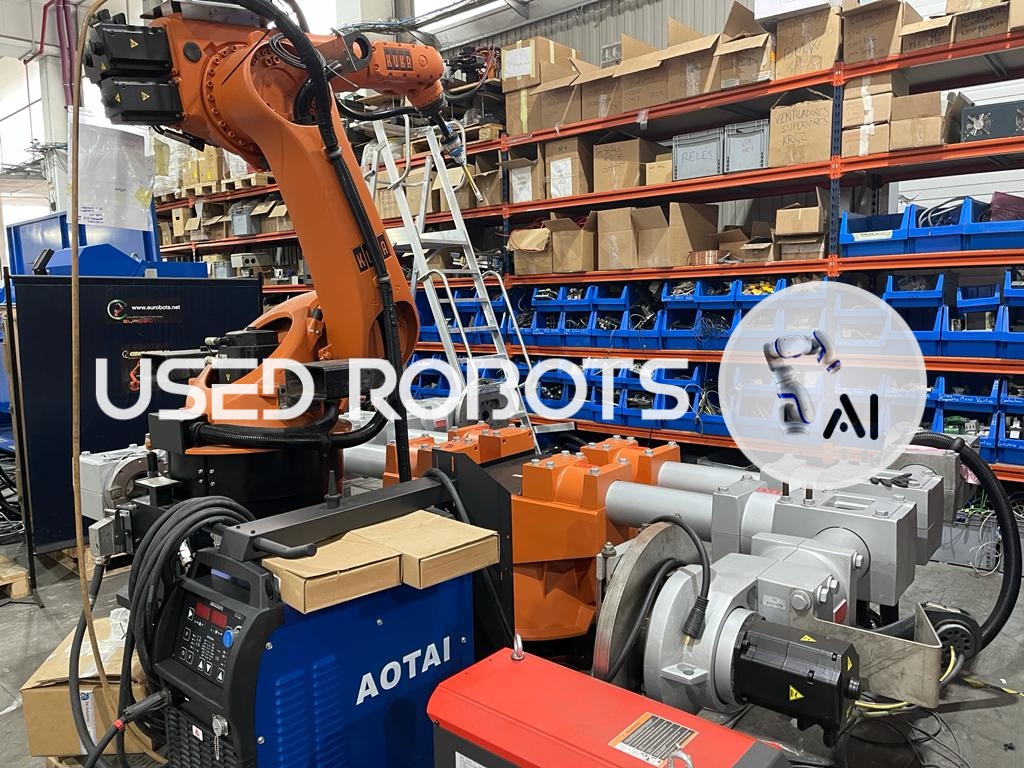

This system comprises a KUKA industrial robot with a suitable power source for arc welding, a torch for welding operations, a positioner for workpiece manipulation, and the necessary control hardware and software. The option to add two additional axes for positioner control enhances the system’s flexibility and functionality in arc welding applications.

- KUKA 6-Axis Industrial Robot (2033mm arm reach): This is the core component of the system and serves as the robotic arm that performs the welding operation. The 6-axis design allows for a wide range of motion, and the 2033 mm arm reach determines how far the robot can reach.

- SKS 400 Power Source or Fronius TPS4000 (400A): These are the power sources used for arc welding. They provide the necessary electrical current for the welding process. The choice between SKS 400 and Fronius TPS4000 depends on your specific requirements and preferences.

- Torch: The welding torch is the end-effector attached to the robot’s arm. It is responsible for delivering the welding electrode and maintaining the arc during the welding process.

- H KUKA Positioner (1.6m tip/tailstock, 500kg payload, 80cm radius): The positioner is a component that assists the robot in manipulating the workpiece. It can rotate and position the workpiece to make welding easier. It includes a maximum payload of 500kg and the radius of rotation 80 cm.

- KRC2 Cabinet with 5.x.x Software Version and Arc Welding Software: The KRC2 cabinet houses the robot controller. The arc welding software is specialized for welding applications and helps the robot execute welding tasks.

- Possibility of Adding a 7th and 8th Axis: to extend the robot’s capabilities by adding two additional servo-controlled axes. These axes can be used to control a positioner, making it easier to position the workpiece for welding. This is a valuable feature for optimizing the welding process and achieving more complex welds.

Reviews

There are no reviews yet.